What’s That: GTL Drilling Fluids

Trade Tensions Continue to Drive Oil Prices Lower

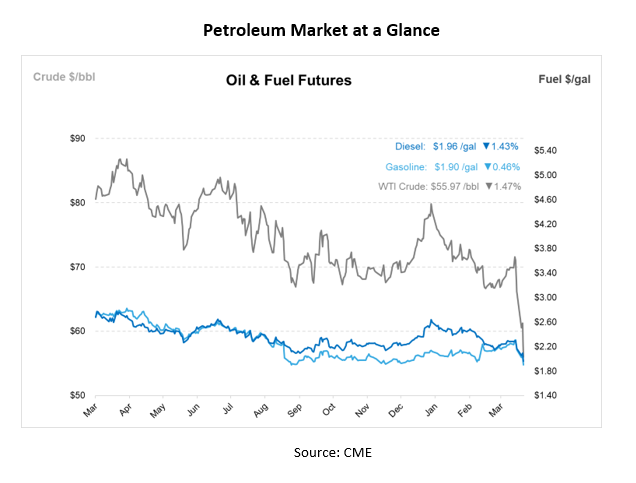

While the trade war continues to rattle global markets, oil prices are falling to their lowest levels seen in years. Brent and WTI crude both fell over $3/bbl to $59 and $55 respectively, as the U.S.-China trade war escalated since yesterday. China raised tariffs on U.S. goods to 84%, while President Trump’s tariffs jumped to 104%. Despite the market turmoil, these tariffs do not target energy products — so the fall in oil prices is driven by broader economic fears.

The wider financial markets are also under pressure. Equity futures and the U.S. dollar are trading lower, while U.S. Treasuries saw their biggest selloff since the pandemic, with 10-year yields spiking to 4.51%. Concerns over global growth and a potential hit to China’s oil demand are adding downward pressure on prices, alongside OPEC+’s decision to raise output by 411,000 barrels per day.

Tariffs are sharply increasing for sectors like consumer durables, industrial machinery, and agriculture. The biggest impacts are being felt in lumber, food, and manufactured goods, not fuel. So, for now, the combination of trade tensions, supply growth, and bearish market risk sentiment is keeping prices low.

______________________________________________________________________________________________________________________________________________________________

GTL Drilling Fluids

Industries such as oil and gas exploration, rely heavily on drilling fluids to ensure operational efficiency and safety. If you’re already using GTL drilling fluids, you know they’re trusted for tough jobs, but do you know what truly sets them apart? Behind every drum of GTL fluid is advanced technology designed not just for performance, but for cleaner, safer, and more efficient drilling operations. In environments where reliability and safety are non-negotiable, GTL fluids deliver low toxicity, excellent lubricity, and a higher flash point to help reduce risks and boost productivity.

In this edition of “What’s That Wednesday,” we’re unpacking the full story behind GTL drilling fluids – how they’re made, where they shine, and why they’re becoming the preferred choice over conventional fluids in challenging drilling environments. Whether you’re drilling onshore, offshore, or tackling unconventional plays, understanding the science and advantages behind GTL fluids will help you maximize their value in your operations.

What are GTL Drilling Fluids?

Derived from natural gas through a chemical conversion process, GTL fluids offer several performance advantages over conventional oil-based fluids. These synthetic base fluids are derived from natural gas through the Fischer-Tropsch process—an advanced chemical conversion method that produces exceptionally pure fluids composed mainly of iso-paraffins and normal paraffins, with only trace amounts of sulfur, aromatics, and other contaminants.

Thanks to their ultra-clean composition, GTL fluids present a significantly lower toxicity profile than traditional diesel-based options, making them safer for both personnel and the environment. A key safety advantage is their higher flash point—approximately 85°C versus 60°C for diesel—which greatly reduces fire risk during handling and storage. In addition to safety, GTL fluids offer excellent lubricity, often improving the rate of penetration (ROP) by 10 to 30 percent. Their consistent performance in a wide range of temperatures and harsh environments makes them a dependable, high-performing solution for modern drilling operations.

What Industries or Practices Use GTL Drilling Fluids?

For industries that rely on diesel-based fluids, GTL drilling fluids offer a cleaner, more advanced alternative. They are necessary for maintaining well control, stabilizing the wellbore, cooling and lubricating the drill bit, and efficiently transporting cuttings to the surface. GTL drilling fluid performance directly impacts drilling speed, safety, and overall project success.

GTL drilling fluids are utilized across a range of industries and applications, including:

- Onshore Drilling: This is the most common use of GTL drilling fluids, driven by the global demand for energy and the growth of land-based drilling projects targeting oil, natural gas, and geothermal resources.

- Offshore Drilling: In deepwater, high-pressure, and high-temperature (HPHT) environments, GTL drilling fluids are specially formulated to maintain wellbore stability and withstand extreme conditions encountered below the seabed.

- Reservoir Drill-In Fluids: GTL drilling fluids are engineered to match the specific characteristics of the reservoir, helping to maximize hydrocarbon recovery while protecting the formation from potential damage.

- Shale Gas Exploration: Drilling operations in shale formations require customized fluids capable of managing complex geological conditions and supporting efficient hydraulic fracturing.

Industry Leaders: Who Paves the Way for GTL Drilling Fluids?

For over 50 years, diesel has been the standard drilling fluid used in both water and land-based operations. However, as the industry shifts toward more sustainable and efficient solutions, lubricant manufacturers have stepped up to meet these evolving requirements. Leading the charge is Shell Lubricant Solutions, a recognized industry leader offering high-quality Gas-to-Liquid (GTL) drilling fluids tailored for a wide range of drilling applications. Shell’s GTL technology transforms natural gas into premium-quality liquid fuels, advanced base oils for lubricants, and other liquid products traditionally sourced from crude oil. The innovative processes that Shell offers are upheld by more than four decades of research, development, and successful commercial implementation. Shell’s GTL drilling fluids offer key performance benefits—making them well-suited for use across diverse environments and challenging conditions.

One standout product, NEOFLO 4633, is a premium GTL-derived base fluid designed for use in both conventional and unconventional drilling operations—on land and offshore. With virtually no aromatic and negligible levels of sulfur or amines, this fluid is not only cleaner but also rooted in a natural gas origin, making it a safe and sustainable choice for modern drilling needs.

Reach out to a lubricant expert at Mansfield Service Partners today to explore our full range of premium lubricant solutions. As a trusted Shell Prestige Distributor, we offer access to Shell’s top-tier products, including the advanced NEOFLO 4633 drilling base fluid. Get in touch with our team and discover how our lubricant solutions can enhance your operations with greater performance, safety, and reliability.