How Lubricants and Service Reduce Repair Costs

If you manage a fleet of vehicles, operate a marina, or are in charge of equipment at a plant or factory — then you know that maintenance is key. Looking after the tools and machines that keep a business healthy and generating revenue is an important responsibility.

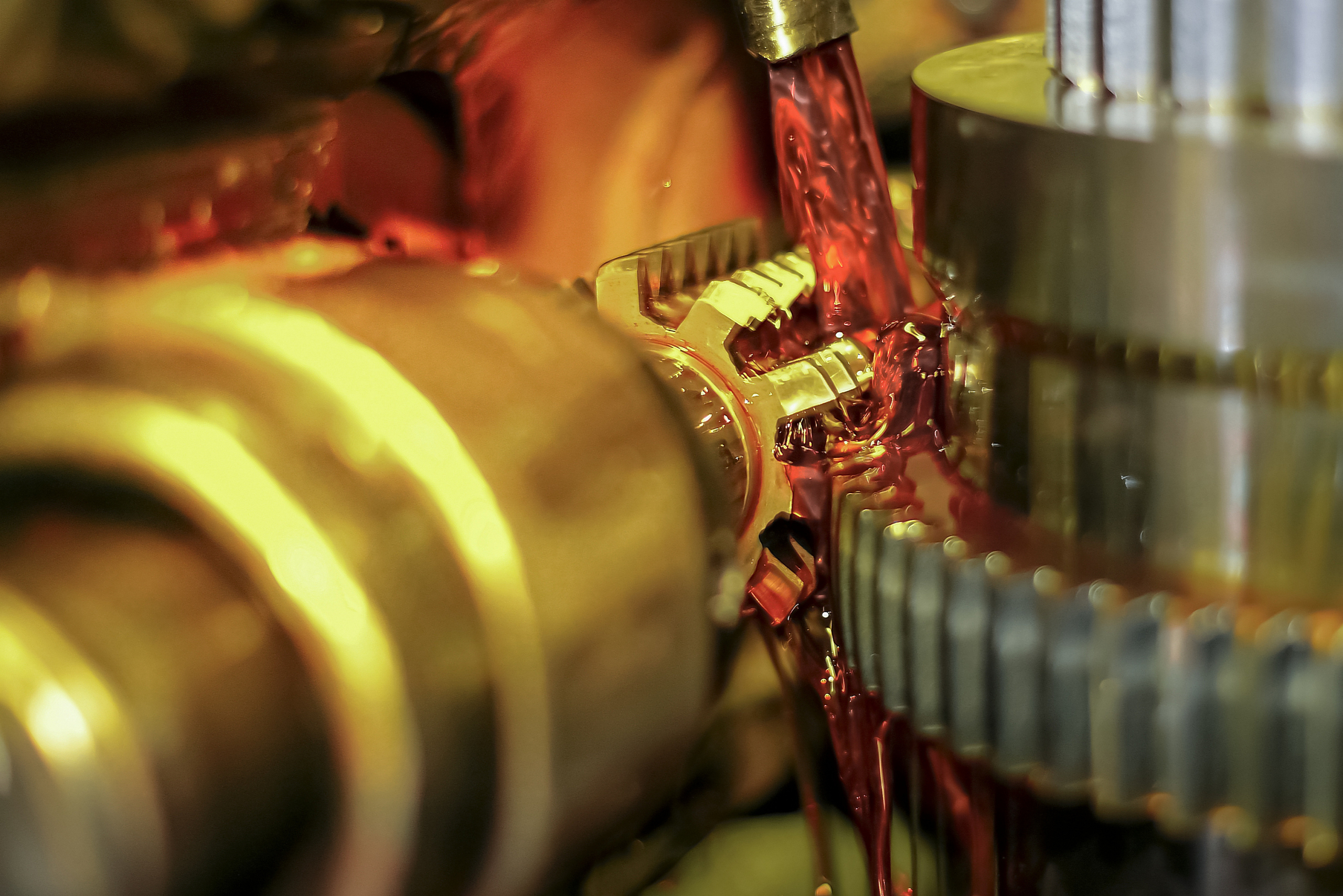

An important aspect of that maintenance duty involves lubricants and service schedules. All machines have moving parts. Anywhere two or more surfaces meet and friction occurs, lubricants are likely needed.

This article is about how staying on top of your lubricant supply and following service schedules saves money on repair costs and more.

The Role of Lubricants in Engines and Machines

Industrial lubricants play a critical role in the operation of machinery. Choosing the right lubricant for the job and following manufacturer guidelines for service intervals will not only save money on repair costs — but can also help avoid unnecessary downtime due to equipment failure and extend the life of your investments.

The pivotal roles lubricants play include:

- Reduce friction between moving parts, minimizing wear and tear.

- Dissipate heat generated by the operation, preventing overheating.

- Prevent corrosion by creating a barrier between parts and corrosive elements.

- Seal gaps in machinery, preventing leakage of gases and liquids.

The Right Tool for the Job — The Right Lubricant for the Job

In the past few decades especially, the machines we use to do our work have changed. Some have become more powerful or more durable. Most of them have become more reliable — but almost all of them have become more complex.

That’s not necessarily a bad thing. More complex machines have brought us new capabilities and functionality. Reduced emissions, more efficiency. There’s a long list of benefits. This new complexity has also changed lubricant needs.

There are good reasons why engineers and designers specify certain lubricants and service schedules. They understand the machines and tools they build better than anyone.

4 Reasons Why Using the RIGHT Lubricant Really Matters

- Resistance to Heat and Pressure: High-quality lubricants are designed to withstand extreme heat and pressure. Using the incorrect lube can lead to the lubricant breaking down rapidly and machine damage or failure.

- Compatibility with Metals and Materials: Different machines are made from different materials. The right lubricant will be compatible with these materials, preventing corrosion and wear. The wrong lube can cause corrosion or wear.

- Optimal Viscosity: The viscosity of the lubricant should be suitable for the operating conditions. Too thick, and it may not flow well. Too thin, and it may not protect well.

- Lubricant Additive Packages: These days most lubricants contain anti-wear agents, rust inhibitors, and detergents that keep the machinery clean. Using poor-quality lubricants often means missing out on one or more of these additives, leading to wear and damage — or worse.

The Right Maintenance + Right Lubricant Saves You Money

Anyone who is managing a business must keep an eye on the balance sheet. Naturally investing in quality industrial lubricants and following recommended service intervals is the right thing to do. But what if we told you that taking lubrication seriously can also save money?

The math is simple. Using the correct lube for the job and following manufacturer guidelines for maintenance may cost you a little more at the onset — but it will save you money and trouble in the long run. Cutting corners on lubrication and service is being pennywise and pound-foolish.

How lubricants save you money:

1.) The right lube at the right time helps avoid breakdowns:

Regularly serviced machinery is less likely to break down unexpectedly, saving you costly repairs. It also means less downtime for equipment, which means better productivity.

2.) Extends the life of your valuable machinery:

Proper lubrication reduces wear and tear, extending the lifespan of your machinery and delaying replacement costs. Considering the cost of today’s diesel engines, pumps, generators, and other parts — this is a significant savings.

3.) Well-lubed machines are more efficient:

The primary job of lubricants is reducing friction. Friction not only causes wear, it also generates heat. That heat is wasted energy, energy that could have been used to do work, but is instead prematurely wearing your machinery down. Well-maintained machinery operates more efficiently, reducing energy costs.

America’s Quality Lubricant Supplier

Mansfield Service Partners began supplying industrial lubricants and fuels way back in 1932. We built our reputation for quality and top-notch service by meeting the needs and exceeding the expectations of our customers.

From our simple beginnings in Houston, Texas to our multi-state operations today — Mansfield Service Partners benefits from the loyalty of our customers because we always put them first.

From 24-hour fuel delivery to industrial lubricants, DEF, and environmental services, like used oil collection — we’ve got you covered.

Contact Mansfield Service Partners today. Reach us at (800) 683-1331 or email any inquiries to info@mansfield.energy